Product Code: BAC

Product Code: SAC/SACN

Product Code: THOR-S

Product Code: BLF/N

Product Code: BHF/N

Product Code: BATN

Product Code: BAF/N (X) (E)

Product Code: SSM/N

Product Code: SSHD/N

Product Code: SS/N

Product Code: CAB/N

Product Code: BDHF/N

What is thermal expansion?

Thermal expansion is a term used to describe the changes in materials that occur as a response to temperature increases or decreases. These changes include shape, volume, and area. In other words, the material expands and contracts according to the temperature it’s subjected to. The warmer the temperature, the more some materials will expand.

Pipework is commonly composed of stainless steel, carbon steel, copper or Multi-Layered Composite Pipe (MLCP). Each has their own formulas to calculate the changes of expansion for different temperatures. This calculation is based on the temperature change, length of pipework, and coefficient of thermal expansion of the material. If thermal expansion changes in pipework are unaccounted for, then pipes are at great risk of bending, bowing, leaks and other damaging effects that result in the failure of your pipework system.

How do expansion bellows, guides and anchors protect pipework?

Fixing damages to pipes as a result of unaccounted for expansion is costly. Luckily, there are precautions you can take to ensure that your hot water and heating systems are protected for a long service life. This includes the utilisation of expansion bellows, anchor brackets and slide guides.

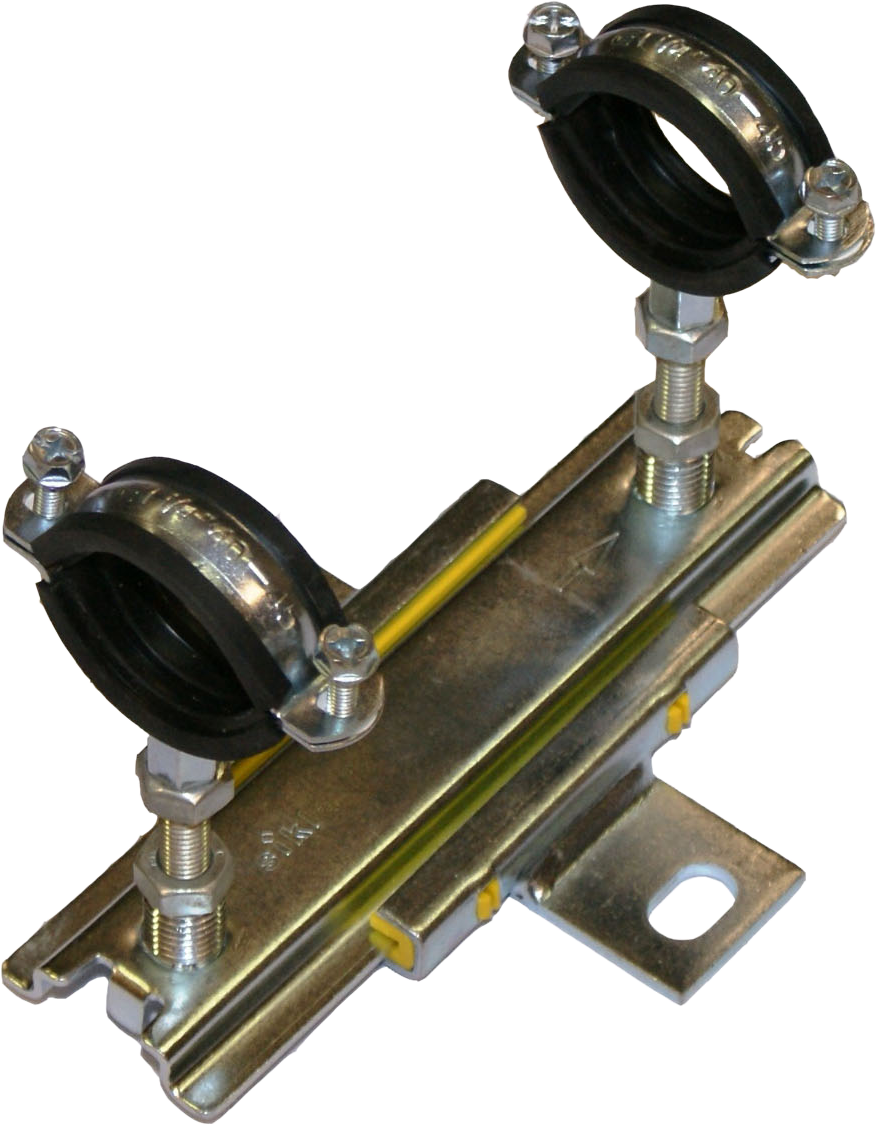

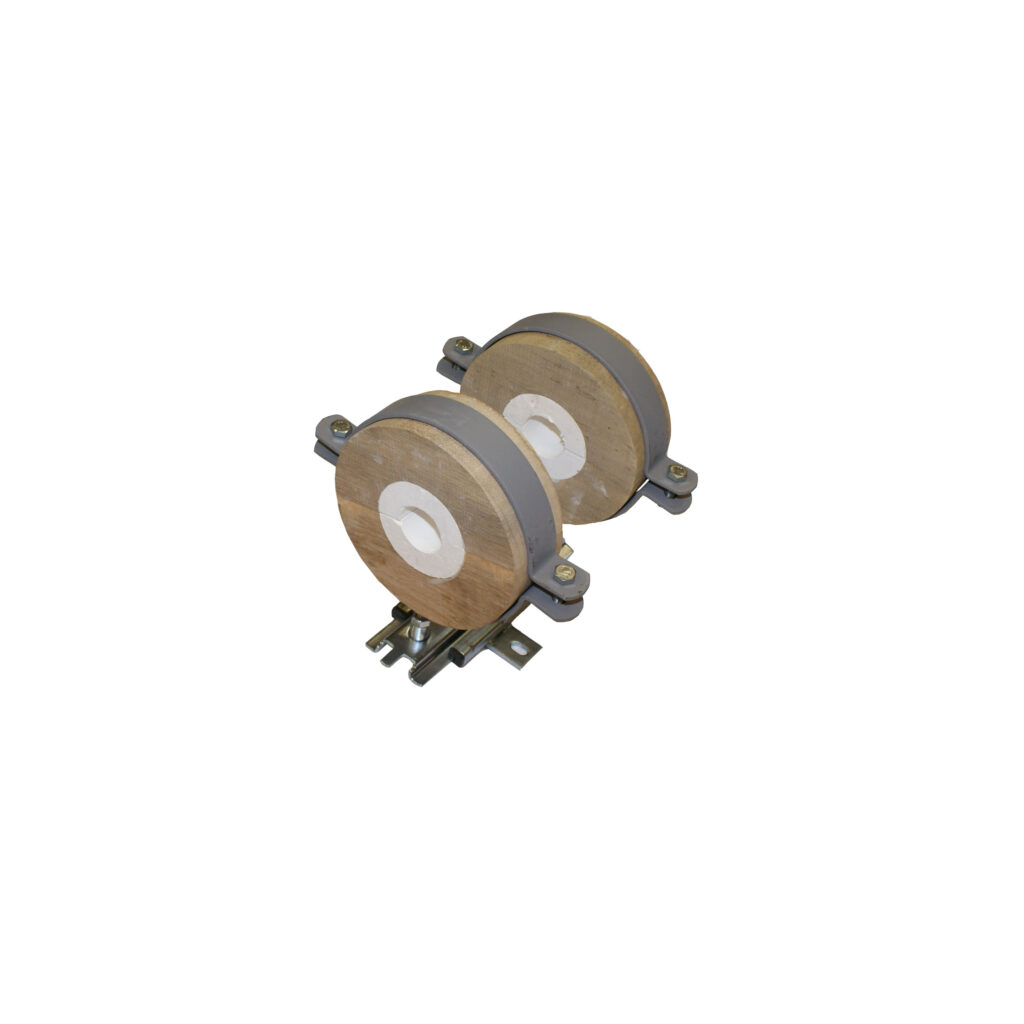

Slide Guides, such as our EMFLEX Slide Guide & Rubber Lined Clip Set, avoid bowing and bending in the pipework by allowing the pipes to move in an axial direction.

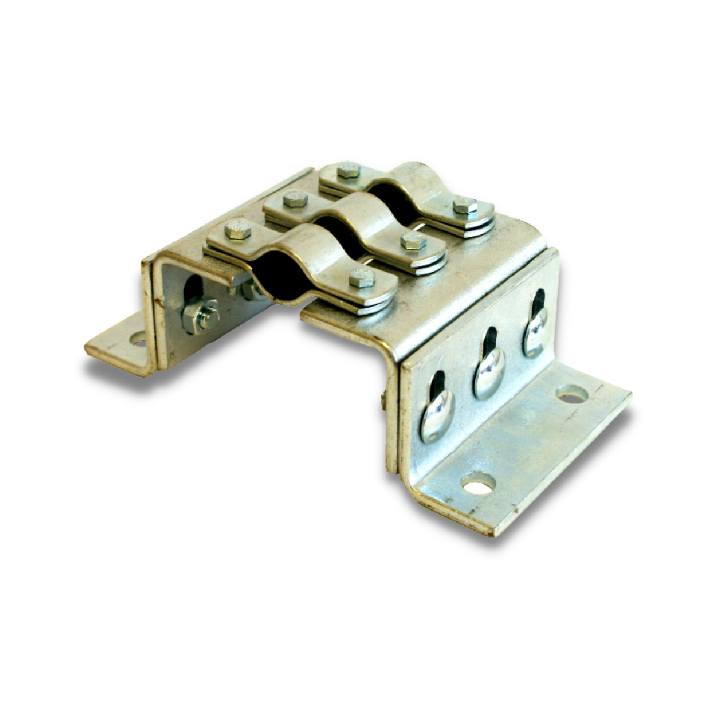

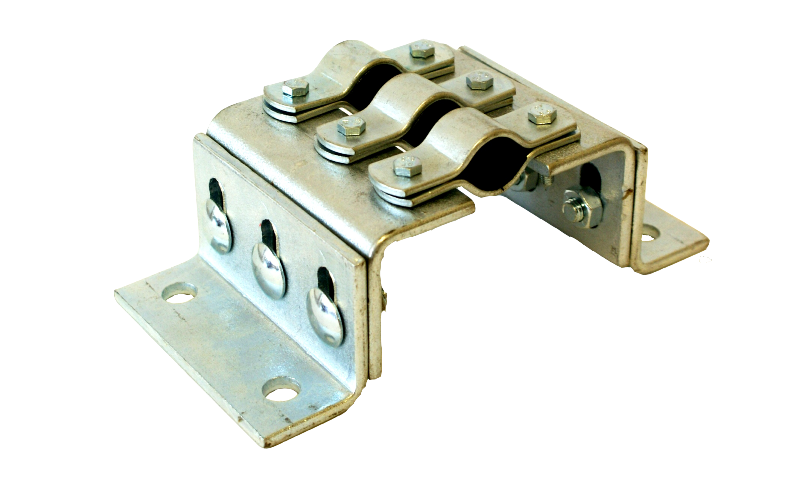

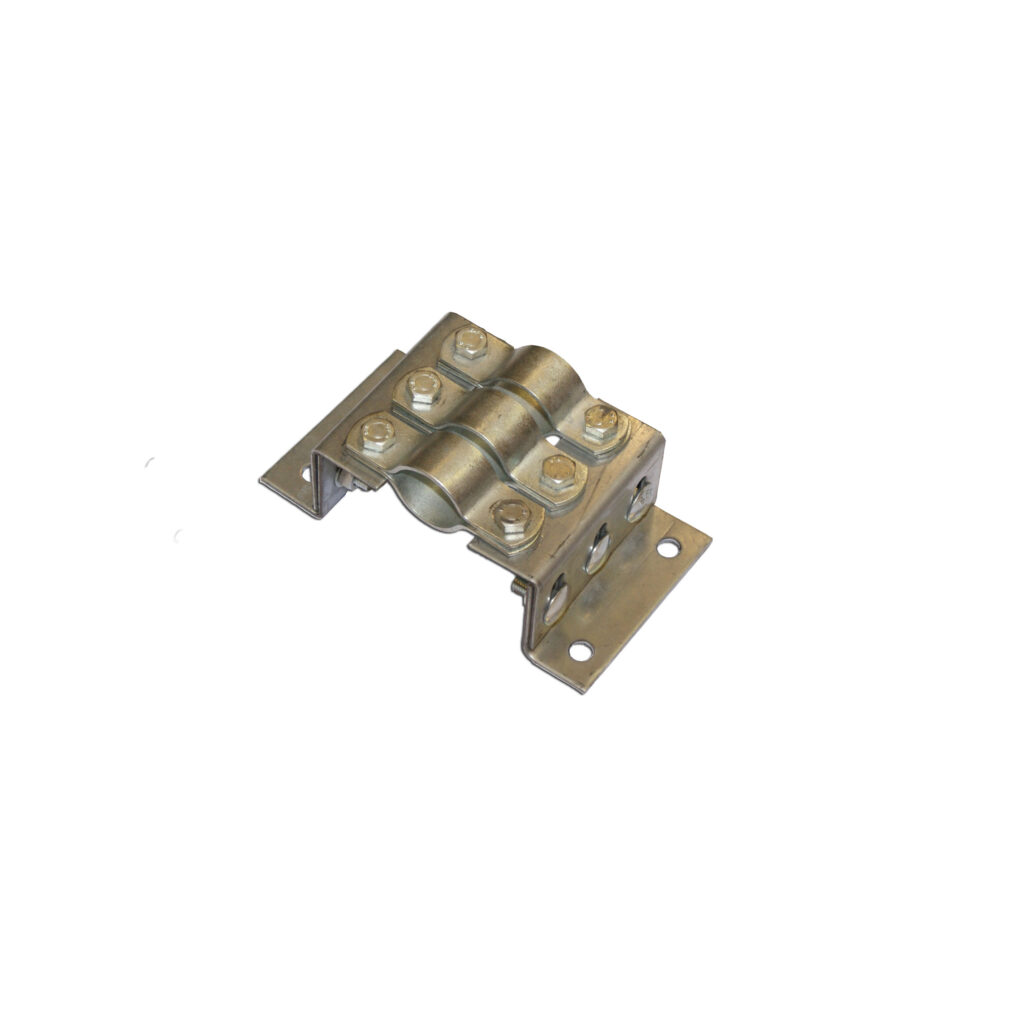

Anchors are used to secure the pipework in place and control movement to prevent any damage. Cleated anchor brackets can be manufactured to any centreline which you require with the use of extended legs, or they can be ‘packed out’ with a Unistrut frame. Our EMFLEX Type CAB/N Anchor Brackets are one of our best selling products, and work in conjunction with our expansion bellows and twin clip slide guide sets.

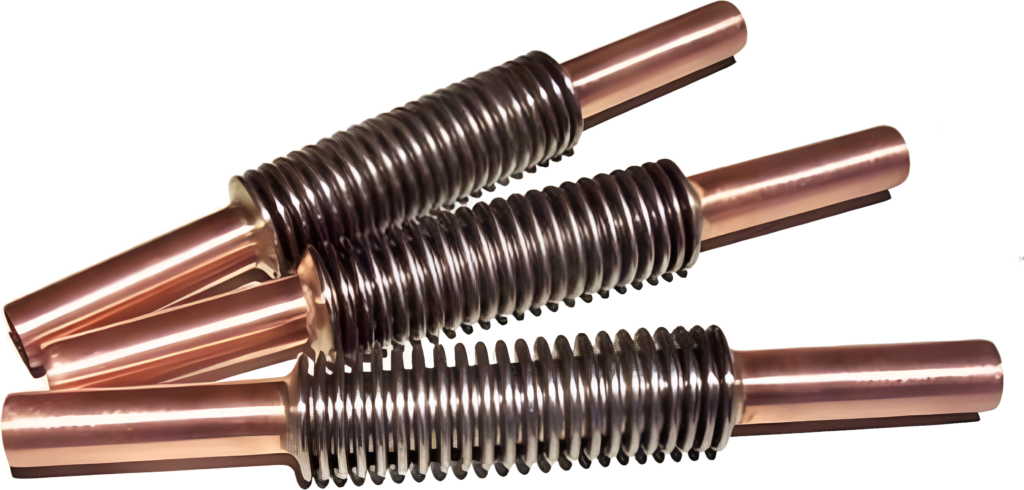

Expansion bellows, such as our Screwed Expansion Joints, work to absorb pipework expansion movements and therefore protect the pipework from expansion movements.

How can Minikin’s help?

Calculating the impact of expansion movements is difficult. Not only do you need to take into account the different properties of your pipework material, but also the routing of your system should be accounted for with changes in direction also having an effect on how your movements can be dealt with. Any mistakes made can also be costly, resulting in pipe breakages and failing systems. To avoid this unnecessary burden, our team at Minikins are here to help.

Our trained experts are equipped to deal with all enquiries, from hospitals, schools or offices to high-rise apartments or large renovations. With over 40 years of leading industry experience, our team are here to help.

It’s important that your expansion is accounted for in the design stage of a project to prevent significant damages from occurring. Once your designs have been sent to us, our experts will examine whether movements can be accounted for in a natural way, or if your pipelines will need additional support to secure their service life.