Slide Guide & Rubber Lined Clip Set

Product Code: SS/N

EMFLEX slide guide and clip sets are essential for the correct operation of AXIAL type expansion joints. A pipeline which contains an expansion joint and is anchored at each end can be considered as a load bearing column. Thus when pressure is applied, guides are necessary to prevent bowing and bending.

Product Type

Illustrations

Additional Information

For use on steel pipelines for LPHW (low pressure hot water). Consists of a plated formed steel sliding component and slide rest, incorporating a threaded plated steel fixing (M10 or M12) complete with a single or double rubber lined pipe clip.

For use on copper pipelines domestic and hot water services. Consists of a plated formed steel sliding component and slide rest, incorporating a threaded plated steel fixing (M10 or M12) complete with a single or double rubber lined pipe clip

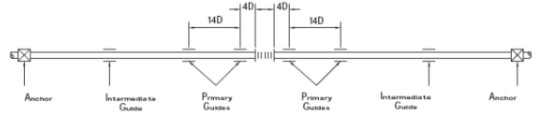

Typical installation 1

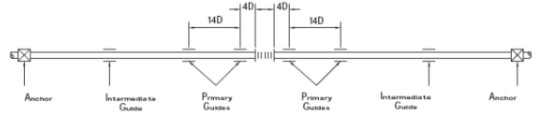

Typical installation 2

Axial expansion joints are designed to absorb movements generally between 25mm and 80mm, although longer movements of 75mm are available on request. They are fitted in the pipeline, in line with the movement. They require an anchor each end of the system to resist the pressure force and to compress the bellows. The following diagrams show two types of typical installations.

We strongly recommend that this type of slide guide be only used on 80mm nominal bore pipework and below. Please see our type SSHD/SSHDN for further details on pipe slide guides for above 80mm NB pipework.

+ -

Emflex

STANDARD SLIDE GUIDES

N.Minikin & Sons LimitedUnit 2B Brickyard Road, Roecliffe, York, YO51 9NS

Email: enquiries@minikins.co.uk Web: www.minikins.co.uk

Tel: 01423 326 789

01423 326 789

N.MINIKINS & SONS LIMITED

MINIKINS.CO.UK

Slide Guide & Rubber Lined Clip SetProduct Code: SS/N

EMFLEX slide guide and clip sets are essential for the correct operation of AXIAL type expansion joints. A pipeline which contains an expansion joint and is anchored at each end can be considered as a load bearing column. Thus when pressure is applied, guides are necessary to prevent bowing and bending.

For use on steel pipelines for LPHW (low pressure hot water). Consists of a plated formed steel sliding component and slide rest, incorporating a threaded plated steel fixing (M10 or M12) complete with a single or double rubber lined pipe clip.

For use on copper pipelines domestic and hot water services. Consists of a plated formed steel sliding component and slide rest, incorporating a threaded plated steel fixing (M10 or M12) complete with a single or double rubber lined pipe clip

Typical installation 1

Typical installation 2

Axial expansion joints are designed to absorb movements generally between 25mm and 80mm, although longer movements of 75mm are available on request. They are fitted in the pipeline, in line with the movement. They require an anchor each end of the system to resist the pressure force and to compress the bellows. The following diagrams show two types of typical installations.

We strongly recommend that this type of slide guide be only used on 80mm nominal bore pipework and below. Please see our type SSHD/SSHDN for further details on pipe slide guides for above 80mm NB pipework.

01423 326 789

N.MINIKINS & SONS LIMITED

MINIKINS.CO.UK

Slide guides are an essential component in pipework systems for the correct operation on axial type expansion joints. When used together, our expansion joints and slide guides prevent bending and bowing in pipes where thermal expansion forces would otherwise cause significant destructive damage.

To protect your systems and avoid costly repairs, our team is here to help. Simply send your designs over to our experts to receive a free consultation. This includes marked-up drawings, product installation guidance, site visits on request and more.

Our EMFLEX slide guides are designed for wall, ceiling or floor mount use. Where expansion joints are used, pipework is subjected to bending-type movements as a result from these external thermal forces. When a guide is used, pipes simply flow naturally to these movements.

For more information, simply explore our data sheets below. Alternatively, you can get in contact with our experts by contacting us on phone or email.