Rubber Flexible Connectors

Product Code: BB

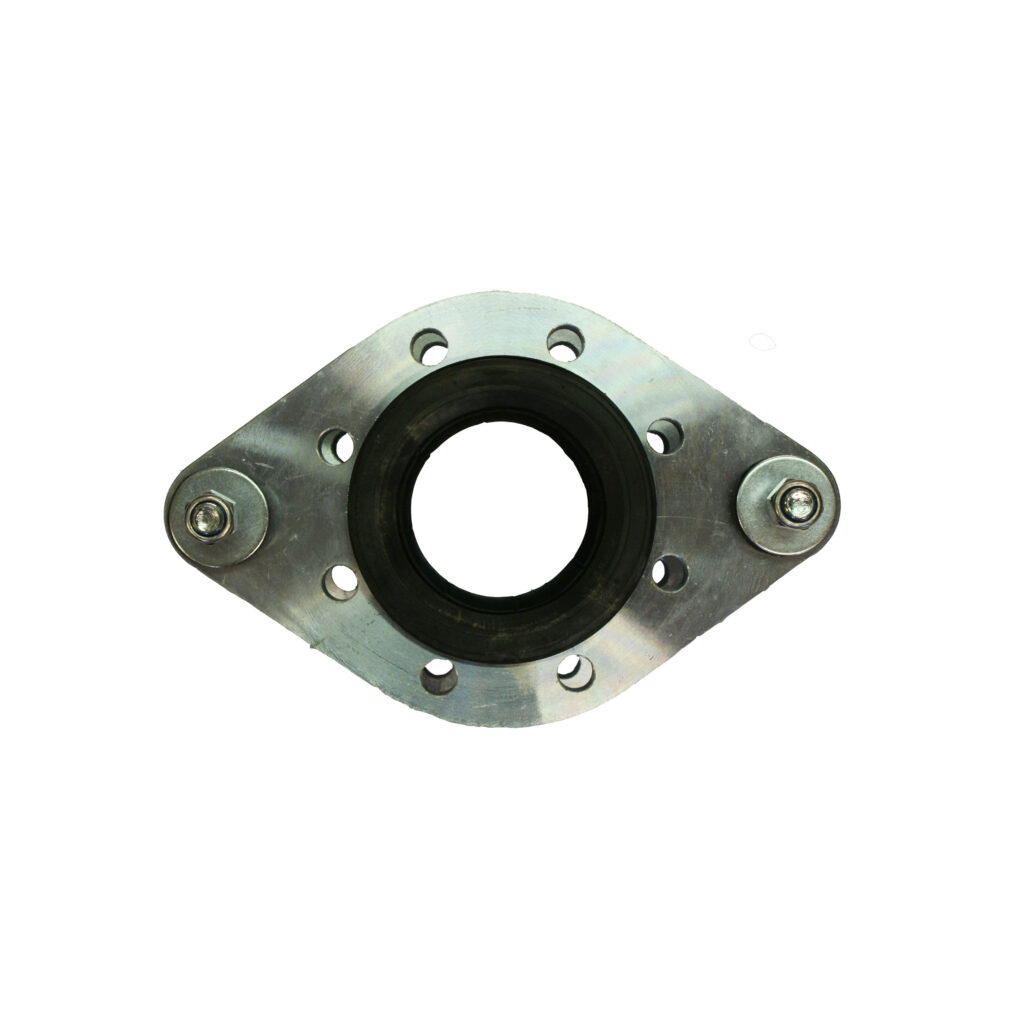

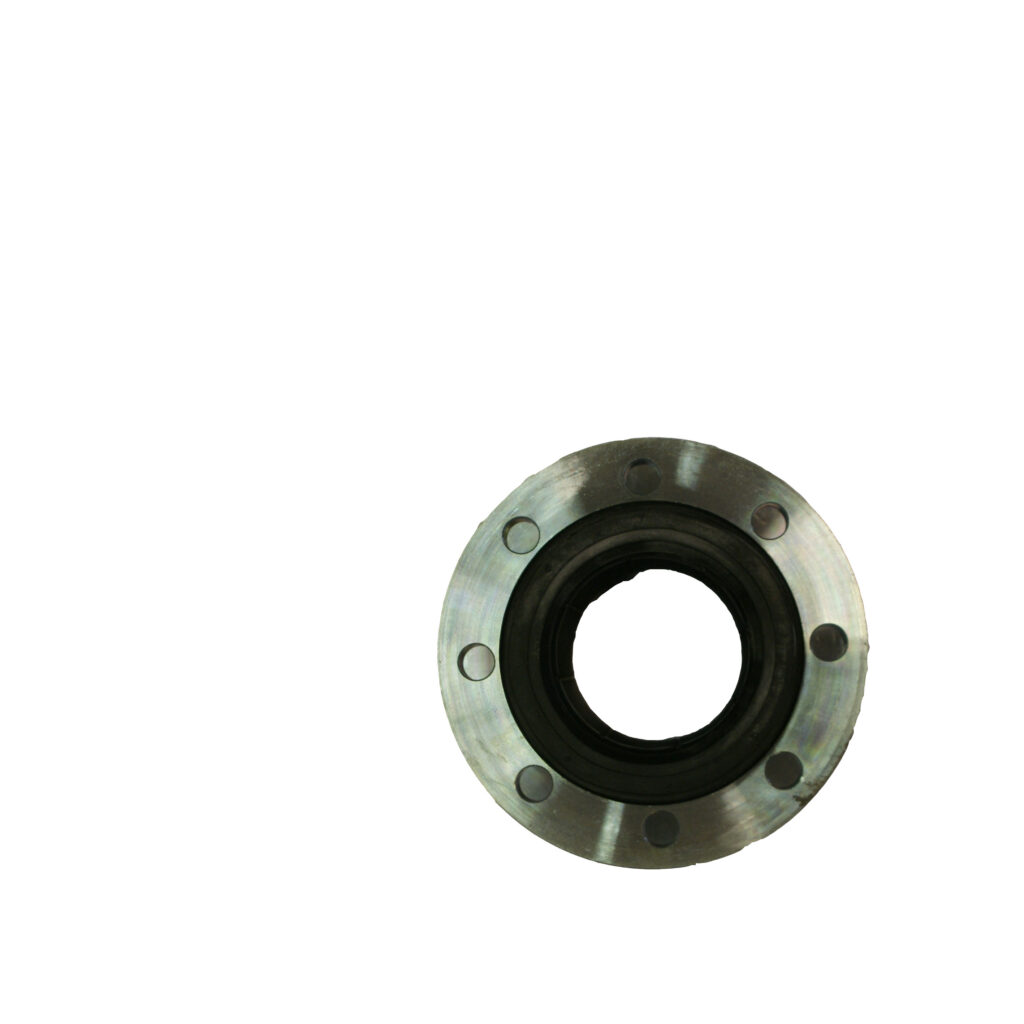

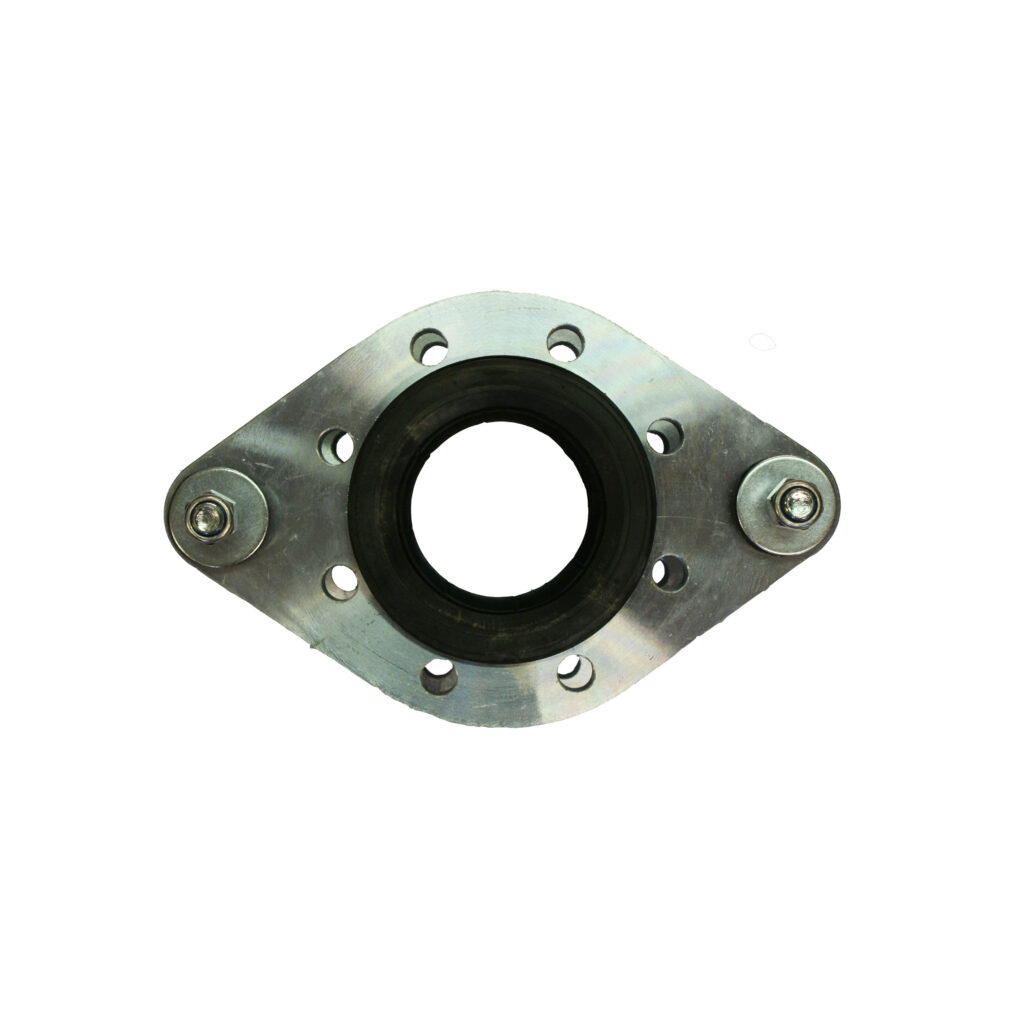

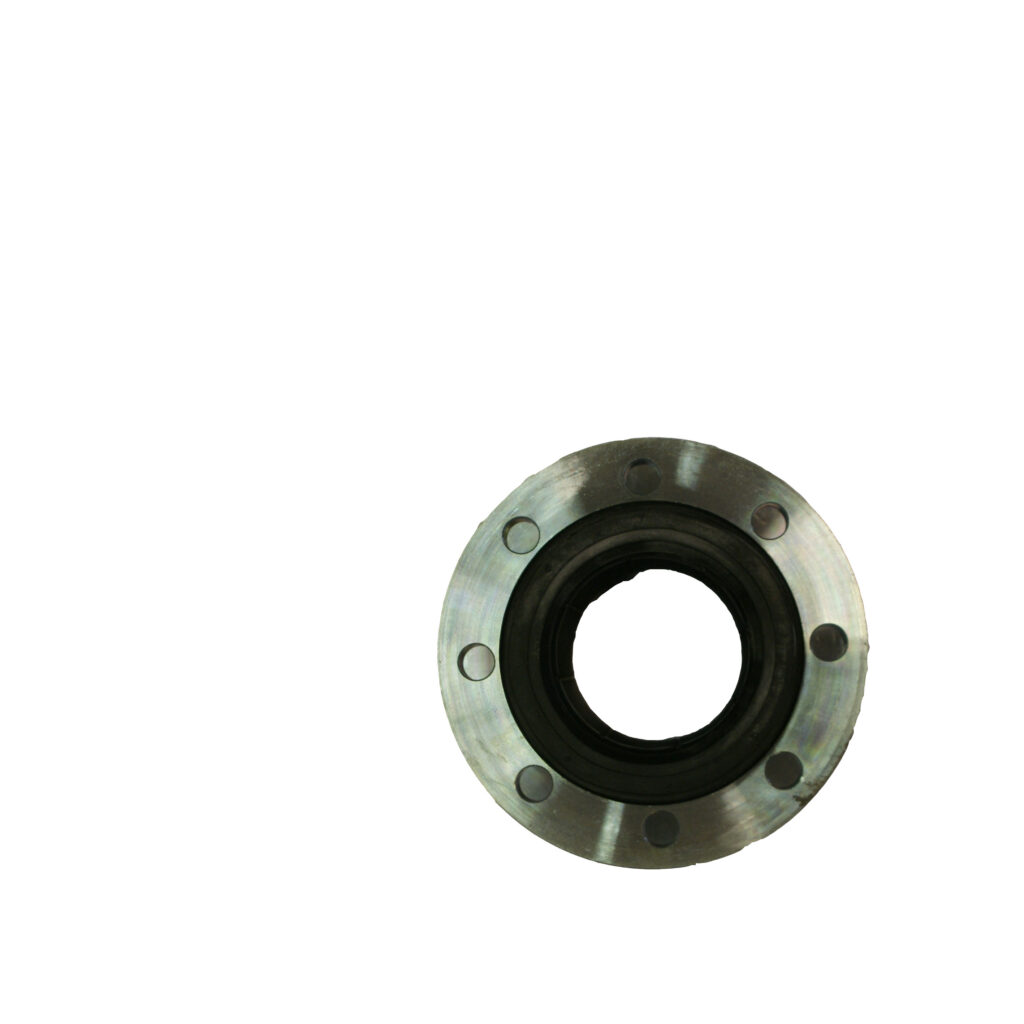

EMFLEX chlorobutyl (often shortened to ‘butyl’) rubber flexible connectors are comprised of a synthetic rubber membrane reinforced with nylon. The collars are wire reinforced and the unit is complete with carbon steel flanges. They are capable of absorbing movement in several directions; axial compression, axial elongation and lateral deflection. A small amount of angular movement may also be allowed. They are normally installed in the pipework to isolate various items of plant which produce noise and vibration. These flexible connectors effectively dampen the transmission of sound and vibration from plant items in building services installations

Product Type

Info Table

Additional Information

Chlorobutyl rubber membrane reinforced with a nylon textile cord and fitted with ‘untied’ or ‘tied’ carbon steel flanges. Suitable for use with hot water and chilled water.

- Nominal Size

- mm

- 25

- 32

- 40

- 50

- 65

- 80

- 100

- 125

- 150

- 200

- 250

- Installed Overall Length

- mm

- 95

- 95

- 95

- 105

- 115

- 130

- 135

- 170

- 180

- 205

- 240

- Untied & Tied Units Axial Compression

- mm

- 8

- 8

- 8

- 8

- 12

- 12

- 18

- 18

- 18

- 25

- 25

- Untied Units Only Axial Elongation

- mm

- 4

- 4

- 4

- 4

- 6

- 6

- 10

- 10

- 10

- 14

- 14

- Untied & Tied Units Lateral Deflection

- mm

- 8

- 8

- 8

- 8

- 10

- 10

- 12

- 12

- 12

- 22

- 22

Vacuum support rings are available

Working Pressure

4 bar (400 kPa) for ‘untied’ units, unless the pipe is secured.10 bar (1000 kPa) for ‘tied’ units with top hat washers.16 bar (1600 kPa) for ‘tied’ units with hemispherical washers.

Test Pressure: 1.5 x Working Pressure

Working Temperature: -10ºC to 100ºC

Key Features

Fully traceable and has the date of manufacture, nominaldiameter, manufacturer, and type permanently moulded into the membrane.

Noise and vibration reduction capabilities. Tied units are fitted with noise absorbing top hat washers.

Design Consideration

Rubber flexible connectors are subject to the same internal pressure force as metal expansion joints and the force is equal to the internal pressure multiplied by the maximum internal area. This force causes the connector to lengthen and tied units are recommended where the working pressure exceeds 4 bar, unless the pipework is secured to restrict movement.

Tie-rods are fitted through oval flanges and to isolate the tierods from the flanges special neoprene top hat washers are used to prevent any metal to metal contact whatsoever, effectively preventing noise transmission.

After installation of TIED UNITS the tie-rod nuts should be checked to have 1mm clearance over the steel washers.

When using with items of plant mounted on vibration isolators, such as springs or inertia bases, then TIED UNITS must be installed.

+ -

Emflex

BB TIED/UNTIED

N.Minikin & Sons LimitedUnit 2B Brickyard Road, Roecliffe, York, YO51 9NS

Email: enquiries@minikins.co.uk Web: www.minikins.co.uk

Tel: 01423 326 789

01423 326 789

N.MINIKINS & SONS LIMITED

MINIKINS.CO.UK

Rubber Flexible ConnectorsProduct Code: BB

EMFLEX chlorobutyl (often shortened to ‘butyl’) rubber flexible connectors are comprised of a synthetic rubber membrane reinforced with nylon. The collars are wire reinforced and the unit is complete with carbon steel flanges. They are capable of absorbing movement in several directions; axial compression, axial elongation and lateral deflection. A small amount of angular movement may also be allowed. They are normally installed in the pipework to isolate various items of plant which produce noise and vibration. These flexible connectors effectively dampen the transmission of sound and vibration from plant items in building services installations

Chlorobutyl rubber membrane reinforced with a nylon textile cord and fitted with ‘untied’ or ‘tied’ carbon steel flanges. Suitable for use with hot water and chilled water.

- Nominal Size

- mm

- 25

- 32

- 40

- 50

- 65

- 80

- 100

- 125

- 150

- 200

- 250

- Installed Overall Length

- mm

- 95

- 95

- 95

- 105

- 115

- 130

- 135

- 170

- 180

- 205

- 240

- Untied & Tied Units Axial Compression

- mm

- 8

- 8

- 8

- 8

- 12

- 12

- 18

- 18

- 18

- 25

- 25

- Untied Units Only Axial Elongation

- mm

- 4

- 4

- 4

- 4

- 6

- 6

- 10

- 10

- 10

- 14

- 14

- Untied & Tied Units Lateral Deflection

- mm

- 8

- 8

- 8

- 8

- 10

- 10

- 12

- 12

- 12

- 22

- 22

Vacuum support rings are available

Working Pressure

4 bar (400 kPa) for ‘untied’ units, unless the pipe is secured.10 bar (1000 kPa) for ‘tied’ units with top hat washers.16 bar (1600 kPa) for ‘tied’ units with hemispherical washers.

Test Pressure: 1.5 x Working Pressure

Working Temperature: -10ºC to 100ºC

Key Features

Fully traceable and has the date of manufacture, nominaldiameter, manufacturer, and type permanently moulded into the membrane.

Noise and vibration reduction capabilities. Tied units are fitted with noise absorbing top hat washers.

Design Consideration

Rubber flexible connectors are subject to the same internal pressure force as metal expansion joints and the force is equal to the internal pressure multiplied by the maximum internal area. This force causes the connector to lengthen and tied units are recommended where the working pressure exceeds 4 bar, unless the pipework is secured to restrict movement.

Tie-rods are fitted through oval flanges and to isolate the tierods from the flanges special neoprene top hat washers are used to prevent any metal to metal contact whatsoever, effectively preventing noise transmission.

After installation of TIED UNITS the tie-rod nuts should be checked to have 1mm clearance over the steel washers.

When using with items of plant mounted on vibration isolators, such as springs or inertia bases, then TIED UNITS must be installed.

01423 326 789

N.MINIKINS & SONS LIMITED

MINIKINS.CO.UK